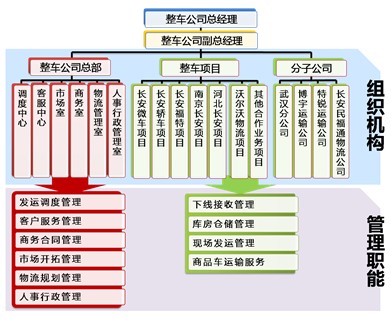

Specific operation matters involved in whole vehicle logistics business of Changan Minsheng APLL Logistics Co., Ltd. are undertaken by Whole Vehicle Company. At present, the Whole Vehicle Company has about 1,200 employees, mainly manages whole vehicle businesses of 6 whole vehicle items and 4 subsidiaries and possesses 9 whole vehicle factory warehouses and 5 main transfer stations. The commercial vehicle storeroom area owned and managed by it reaches 1,900,000m2 (400,000m2 owned). The quantity of storage and shipments reached 1.5 million sets in 2012.

1) Content and Distribution of Whole Vehicle Logistics

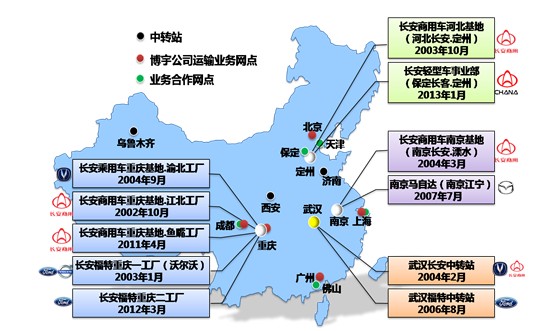

Currently, the whole vehicle logistics of Changan Minsheng APLL Logistics Co., Ltd. mainly includes commercial vehicle storage management, shipment management, program planning & design and value-added services, and the existing whole vehicle logistics business is mainly distributed in Chongqing, Nanjing, Dingzhou, Wuhan and other cities.

2) Capacity of Whole Vehicle Logistics

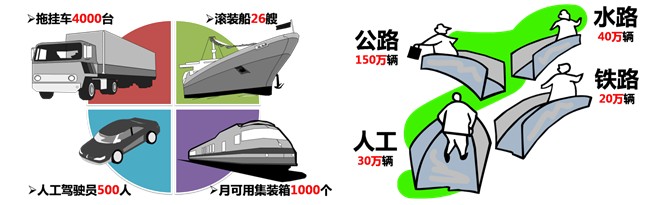

Existing controllable transport capacity of Changan Minsheng APLL Logistics Co., Ltd.: 4,000 articulated vehicles, 26 roll-on-roll-off ships, 500 drivers and 1,000 monthly available railway containers. The annual transport capacity of whole vehicle is 2.4 million sets.

Chongqing Changan Minsheng Boyu Transportation Co., Ltd. is a wholly-owned subsidiary of Changan Minsheng APLL Logistics Co., Ltd. It now has 100 articulated vehicles and 202 drivers. Moreover, it has set transport network point in places such as Chongqing, Shanghai, Guangzhou and Chengdu. By the year of 2015, the quantity of its self-owned vehicle will reach 200, and the number of its drivers will increase to 410. Chongqing Terui Transportation Service Co., Ltd. is a wholly-owned subsidiary of Changan Minsheng APLL Logistics Co., Ltd., and now it has 30 articulated vehicles.

Changan Minsheng APLL Logistics Co., Ltd. has 11 large commercial vehicle roll-on-roll-off ships at present, which accounts for 75% of Yangtze River’s transport capacity. Currently, its monthly water transport capacity exceeds 35,000 sets. In 2014, it will successively have six 900-frieght-space roll-on-roll-off ships, with newly added water transport capacity of 15,000 sets.

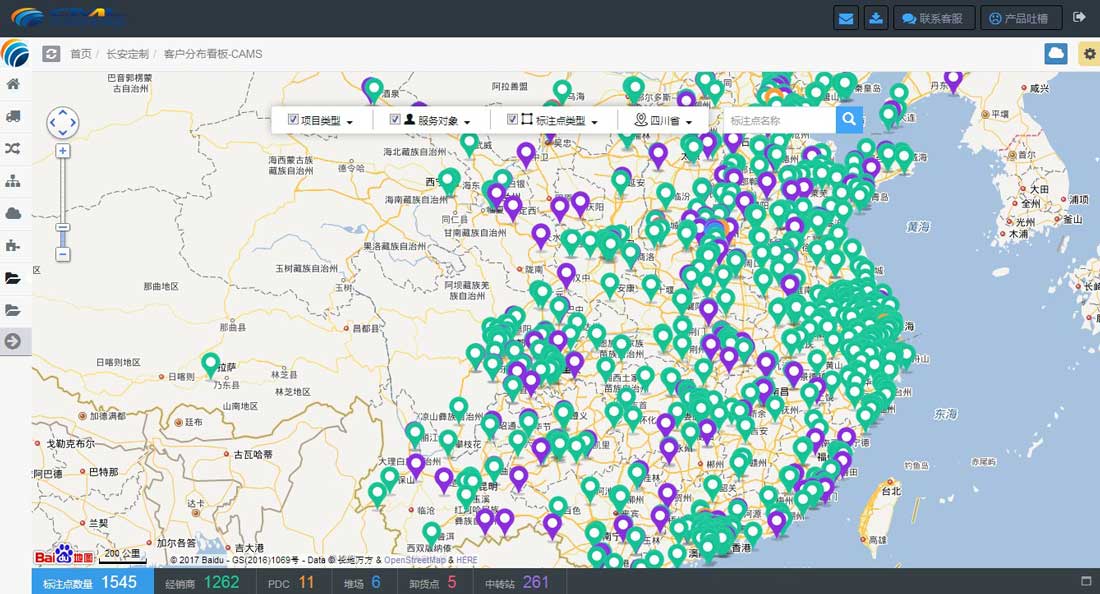

3) Management Information System Platform of Whole Vehicle

The company established the Changan Minsheng Management Information System Platform for Whole Vehicle Logistics (TMS) in 2011; the platform is mature and reliable, taking the lead in the industry in China. The platform realizes information sharing among Changan Minsheng APLL Logistics Co., Ltd., carriers, main engine plants and dealers and achieves resource integration & deployment of each base and uniform control of transport capacity.

4) Future Development

Changan Minsheng APLL Logistics Co., Ltd. is gradually making and forming a nationwide logistics network distribution based on bases, transfer stops and wharfs, so as to form a transport-capacity-assured safety system with main shipment methods of road, water and railway transport.

5) Serve Customers and Partners

With several core advantages in whole vehicle logistics, Changan Minsheng APLL Logistics Co., Ltd. is willing to create win-win benefit with large main engine plants and logistics companies.

a. Provide supply chain integration service of whole vehicle logistics.

b. Create nationwide transport capacity network distribution, set several transport modes to assure supply, and have transport capacity advantages of Yangtze River commercial vehicle roll-on-roll-off ship.

c. Possess mature and reliable whole vehicle management information system with leading advantages, and have a whole set of advanced management practices and operation procedures.

d. Have a mature whole-vehicle logistics management team with over 300 persons, and possess successful management experience in several whole vehicle projects.

By investing and constructing delivery centers, the company provides standard parts storage and delivery service for main engine plants, realizing driving-model lean production and JIT and JIS delivery of materials, reducing logistics cost of main engine plants and part suppliers, and improving production efficiency of main engine plants.

The company has over 20 specialized auto part storage and delivery centers, with total area exceeding 300,000m2. The annual JIT delivery capacity of auto parts exceeds 2.4 million sets; the annual JIT and JIS delivery capacity of engine parts exceeds 2.6 million sets; and the types of delivered auto parts is approximately 40,000.

The company receives and breaks down procurement orders issued by main engine plants, makes goods receiving plan, designs goods receiving line and procedure, reasonably dispatches goods receiving vehicles and represents the main engine plants to handle picking, transport and delivery of goods at the places of suppliers and to conduct real-time tracking and monitoring on goods in transit. The advantages are: separate freight rates; improves loading rate of transport vehicle; optimizes inventory of main engine plants and suppliers; reduces quality loss; improves visualization, reliability and controllability of parts supply; and realizes timely supply.

The goods receiving logistics of the company now covers over 150 suppliers in Southwest Region, Southern China, Eastern China, Central China, Northern China and Northeast Region, with annual service capacity exceeding 30,000TEU.

The company has automatic tire and hub assembly line including robot press fitting, air inflation, optimization, initial inspection, re-inspection balancing machine, etc. and specially engages in tire assembly and relevant value-added businesses. The company is the first-level supplier of Changan Ford as well as its largest tire assembly and supply enterprise in China, with annual tire assembly capacity exceeding 2 million sets.

The company conducts door-to-door service of global cargo transport and provides sea, air, river, railway and road transport services for import & export of cargos such as auto parts, commercial vehicles and equipment, which includes ship chartering and space booking, dynamic monitoring, preparation and handover of shipping document, “customs declaration, commodity inspection, quarantine of animals and plants, and health quarantine”, cargo handover, expense settlement and other agency service.

The international freight forwarding service of the company covers and extends to each continent of the world, and the annual international freight forwarding quantity exceeds 50,000TEU.

Attention US